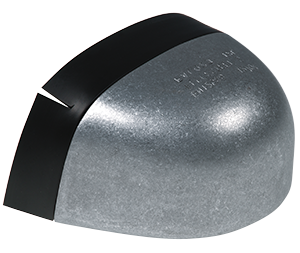

Safety shoes

Safety footwear in accordance with DIN EN ISO 20345 and occupational footwear in accordance with DIN EN 20347 are part of your personal protective equipment and are tested in accordance with DIN EN ISO 20344.

Safety footwear is divided into 2 basic requirements:

• Basic requirement I: shoes made from leather or similar materials

• Basic requirement II: solid rubber shoes or full polymer shoes (Wellington boots)

The basic requirements are each subdivided into categories:

Basic requirement I:

• Category S1/O1: closed heel area, anti-static properties, energy absorption in the heel area

• Category S1P/O1P: in addition to the requirements in S1/O1, there is penetration resistance

• Category S2/O2: in addition to the requirements in S1/O1, there is the test against water penetration and water absorption

• Category S3/O3: in addition to the requirements in S1/O1 and S2/O2, there is penetration resistance and a profiled outsole

Basic requirement II:

• Category S4: Wellington boots with anti-static properties, energy absorption in the heel area

• Category S5: in addition to the requirements in S4, Wellington boots with penetration resistance and a profiled outsole

Additional requirements:

• Symbol P: Penetration resistance

• Symbol A: anti-static properties

• Symbol HI: heat insulation

• Symbol CI: cold insulation

• Symbol E: energy absorption in the heel area

• Symbol WRO: water penetration and absorption

• Symbol HRO: behaviour towards contact heating

Slip resistance of the outsole:

• SRA = Slip resistance on floors made from ceramic tiles with SLS (sodium lauryl sulphate solution)

• SRB = Slip resistance on steel floors with glycerol

• SRC = Passed test SRA +SRC

The safety footwear is also identified by its height:

• Shoe shape A: low shoe

• Shoe shape B: low boot

• Shoe shape C: medium-height boots

The upper heights maynot be lower than those specified in the standard.

Safety footwear must be visibly and permanently labelled:

• CE mark

• Type identification (kit)

• Manufacturer (holder of the type test certificate)

• Shoe size (including for orthopaedic safety footwear)

• Category (S1/O1, S1P/O1P, S2/O2, S3/O3)

• Manufacturing date (at least month and year)

• Article number (upper design)

• Applied standard (20345/20347)

• Country (country of the type test)

• Training number (for Orthopaedic Safety Footwear identifies the company which brings the shoe into circulation)

The regulations of type testing also apply for custom-made orthopaedic safety footwear, semi-orthopaedic safety footwear or series-produced safety footwear which have been orthopaedically modified or fitted with orthopaedic inserts, and the footwear may not be put on the market without a test.

DGUV rules 112-191

The DGUV (German Statutory Accident Insurance) rules for health and safety at work serve the prevention of accidents at work, occupational illnesses and work-related health risks. The DGUV rules 112-191 deal with the use of foot and knee protection.

Solutions from THANNER

THANNER has offered type-tested safety footwear and solutions in the orthopaedics sector for many years. The production of uppers and shoes in-house in Höchstädt an der Donau enables a large number of special designs (other heights, outsole dimensions, colour and material options, ankle counters....) to be offered.

The type examination is only valid, if the current assembly instructions and order processing data published in the current brochure "Perfect Protection" has been observed.

1. Ready-made safety footwear for shoe adaptation and insert supply:

• 5 models from Stabilus with test

• S1, S3 • Shoe sizes: 39 to 47

• ESD

• Shoe adaptations: raising of inside and outside edge, shortening by up to 3.5 cm, rocker soles

• Insert supply: Thermoplastic blank with cover • Billing: DGUV contract requirements level I

2. Semi-orthopaedic safety footwear:

• Safety footwear with a significantly higher volume and the ability to incorporate ankle-reinforcing elements.

• Shoe sizes: 38 to 53 • S1, S2, S3

• ESD

• Shoe adaptations: raising of inside and outside edge, shortening by up to 3.5 cm, rocker soles

• Insert supply: customised insert development by orthopaedic shoe maker, insert cover by Thanner

• Stability shoe: safety footwear with 4 reinforcing elements in the ankle area

• Paralysis boot: safety footwear with 4 reinforcing elements in the ankle area, peroneus reinforcement in the heel area and tongue reinforcement

• Billing: DGUV contract requirements level I

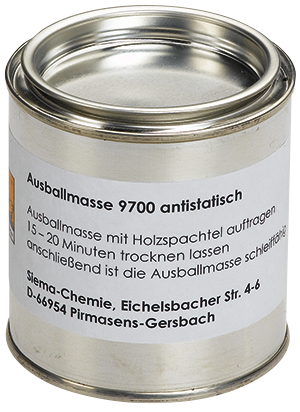

Semi-orthopaedic safety footwear for diabetics:

• Safety shoe for diabetics with a very high toe cap, diabetic lining and plenty of space for diabetic inserts up to 1 cm in the ball area.

• Shoe sizes: 39 to 48

• S3

• Shoe adaptations: raising of inside and outside edge, shortening by up to 3.5 cm, rocker soles

• Insert supply: customised insert development by orthopaedic shoe maker, insert cover by Thanner

• Stability shoe: safety footwear with 4 reinforcing elements in the ankle area

• Paralysis boot: safety footwear with 4 reinforcing elements in the ankle area, peroneus reinforcement in the heel area and tongue reinforcement

3. Custom-made orthopaedic safety footwear:

• A variety of 7 type-tested kits for custom-made orthopaedic safety footwear

• 123 shoe models

• Shoe sizes 37 to 53

• S1/O1, S1P/O1P, S2/O2, S3/O3

• ESD

• The shoes must be produced using a customised last

• Shortening in the foot bed by up to 8 cm in the heel area available in the versions S1P and S3

• Insert covers: leather or microfibre, perforated and unperforated

• Modifications in the sole area: raising of the inside and outside edge, shortening by up to 3.5 cm, rocker soles

• Lasting options:

- Acquisition of a kit for self-lasting

- partial lasting at Thanner

- full lasting at Thanner

• Billable on the basis of the DGUV contract requirements level II (with lasting at Thanner) or requirements level III (with lasting in-house)

4. Safety shoes with chainsaw protection in accordance with DIN EN ISO 17249:2012

With the upper model "Cutter" for the first time it is possible to produce type tested safety footwear with chainsaw protection in according with DIN standard.

• A variety of type-tested kits for custom-made orthopaedic safety footwear

• Two different colour variations

• Shoe sizes 37 to 50

• S3

• Shortening in the foot bed by up to 8 cm in the heel area

• Insole supply: Individual insole construction by orthopaedic shoemaker

• Insert covers: leather or microfibre, perforated and unperforated

• Modifications in the sole area: raising of the inside and outside edge, shortening by up to 3.5 cm, rocker soles

• Lasting options:

- only full lasting at Thanner

The information sheet for correct using of safety footwear with chainsaw protection must be handed out the patient. It is important to note, that the employer have to perform a practical instruction for correct using of footwear.

Semi-orthopaedic safety footwear for modifications in the sole area and insole supply

Brochure Vithana

Semi-orthopaedic paralysis boot as safety shoe

Ankle stiffener for semi-orthopaedic shoe

Brochure stability shoes and paralysis boots

Brochure Vithana

Semi-orthopaedic safety shoe for diabetics

Ankle stiffener for semi-orthopaedic shoe

Orthopaedic safety footwear with chainsaw protection

Brochure Perfect Protection